ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

- Home

- Carbon Steel

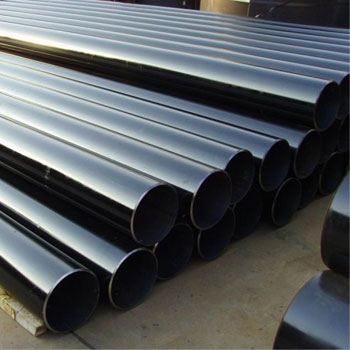

ASTM A333 Grade 6 Carbon Steel ERW Pipes, A333 Gr. 6 Welded Tube, A333 Gr. 6 Carbon Steel Pipes, ASTM A333 Gr. 6 Carbon Steel Spiral Welded Tube at Best Price in India.

VM Energy Solutions INC is a famous supplier and stockist of ASTM A333 Grade 6 Carbon Steel Pipes, which gives better creep, strain-to-rupture and tensile strength than different steels. ASME SA 333 Grade 6 Carbon Steel ERW Pipes are also used in nuclear fueled power technology plants, chemical and petrochemical engineering equipment, etc. It is also used in chemical engineering ships, petrochemical, pulp and paper industries, capacitors in power technology, etc. It demonstrates a low rate of scaling in regular atmospheres at temperatures as much as 1600 Degree F – 1650 Degree F (871 Degree C - 899 Degree C). One exception for this steel, but, is strongly oxidizing acids along with nitric acid. The mixture of molybdenum and nitrogen on this alloy is in particular powerful in improving resistance to pitting and crevice corrosion.

- ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes Standard Specification

- Different Forms of ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

- Tensile Requirements FOR astm a333 Grade 6 seamless pipes

- ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes Chemical Composition

- ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes Mechanical Properties

- Thickness Chart Of ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

- Weight Chart Of ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

- Largest Inventory Of ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

The major exception for these ASTM A333 Grade 6 carbon steel round tubes is in environments corrosive enough to cause intergranular corrosion of fillet welds and thermal effect zones. They are also widely used to treat hot natural and fatty acids. The nitrogen contained in this steel acts as a strengthening agent and provides the steel with better yield strength. It gives decreased inter-granular precipitation of chromium carbides in the course of welding and strain relieving. Annealing on this alloy is executed at 1010 Degree C – 1121 Degree C (1850 Degree F – 2050 Degree F), which must be accompanied via way of means of rapid cooling.

ASTM A333 Grade 6 Carbon Steel Round Pipe, ASTM A333 Gr. 6 Carbon Steel Welded Pipes, ASTM A333 Grade 6 Carbon Steel Welded Pipes, CS A333 Gr. 6 Seamless Pipes, ASTM A333 Gr. 6 Carbon Steel Capillary Tubing Supplier in Mumbai, India.

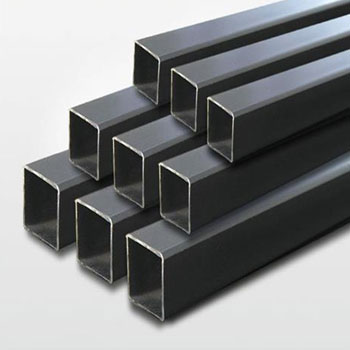

In procedures in which condensation of sulphur-bearing gases occurs, ASME SA 333 CS Grade 6 Square Pipes is much more proof against assault on the factor of condensation than traditional alloy. It gives terrific resistance in applications in which infection is favoured to be saved to a minimal. It is utilized in Food and Beverage Processing, Petroleum Refining, Power Generation — condensers, Pulp and Paper, etc. It shows that the compositions include accelerated tiers of molybdenum and nitrogen respectively. Our provided product is extraordinarily appreciated and preferred via way of means of the clients, as a result of the dimensional accuracy and durability.

We Keep Bulk Stock Of ASTM A333 Gr. 6 Carbon Steel WNRF Pipes, A333 Gr. 6 Carbon Steel Seamless Tube at Our Stockyard, Check A333 Grade 6 Carbon Steel Pipe Dimension, Buy Carbon Steel A333 Gr. 6 Hexagonl Pipe at an Affordable Price In India.

ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes Standard Specification

| Grade | ASTM A333 Gr.6 Carbon Steel |

| Size | 1/4” NB to 30” NB |

| Standard | ASTM A 333, ASME SA 333 |

| Form | Round, Square, Rectangular, Hydraulic Etc |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Length | Single Random, Double Random & Cut Length. |

| Type | Seamless / ERW / Welded / Fabricated / EFW |

| End | Plain End, Beveled End, Treaded |

Different Forms of ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

ASTM A333 Gr. 6 Carbon Steel Seamless Pipe

ASTM A333 Gr. 6 Carbon Steel Welded Pipe

ASTM A333 Gr. 6 Carbon Steel EFW Pipe

ASTM A333 Gr. 6 Carbon Steel ERW Pipe

ASTM A333 Gr. 6 Carbon Steel Tubes

ASTM A333 Gr. 6 Carbon Steel Square Pipe

ASTM A333 Gr. 6 Carbon Steel Hollow Pipe

Tensile Requirements FOR astm a333 Grade 6 seamless pipes

| Grade 1 | Grade 6 | Grade 6 | |||||

| psi | MPa | psi | MPa | psi | MPa | ||

| Tensile Strength, min | 55,000 | 380 | 65,000 | 450 | 60,000 | 415 | |

| Yield Strength, min | 30,000 | 205 | 35,000 | 240 | 35,000 | 240 | |

| Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | ||

| Elongation in 2 in. or 50 mm, (or 4D), min, %: | |||||||

| Basic minimum elongation for walls 5/16 in. [8 mm] and over in thickness, strip tests, and for all small sizes tested in full section | 35 | 35 | 30 | 20 | 30 | 16.5 | |

| When the standard round 2-in. or 50-mm gage length or proportionally smaller size test specimen with the gage length equal to 4D (4 times the diameter) is used | 28 | 20 | 22 | 14 | 22 | 12 | |

| For strip tests, a deduction for each 1/32in. [0.8 mm] decrease in wall thickness below 5/16 in. [8 mm] from the basic minimum elongation of the following percentage | 1.75 | 1.25 | 1.50 | 1.00 | 1.50 | 1.00 | |

| Elongation in 2 in. or 50 mm, min, %: | |||||||

ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes Chemical Composition

| Chemical composition % | |||||||||

| Grade | 1 | 3 | 4 | 6 | 7 | 8 | 9 | 10 | 11 |

| C,max | 0.3 | 0.19 | 0.12 | 0.3 | 0.19 | 0.13 | 0.2 | 0.2 | 0.1 |

| Mn | 0.40-1.06 | 0.31-0.64 | 0.5-1.05 | 0.29-1.06 | 0.9,max | 0.9,max | 0.4-1.06 | 1.15-1.5 | 0.6,max |

| P,max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| S,max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

| Si | – | 0.18-0.37 | 0.08-0.37 | 0.1,min | 0.13-0.32 | 0.13-0.32 | … | 0.1-0.35 | 0.35,max |

| Ni | – | 3.18-3.82 | 0.47-0.98 | – | 2.03-2.57 | 8.4-9.6 | 1.6-2.24 | 0.25,max | 35-37 |

| Cr | – | – | 0.44-1.01 | – | – | – | – | 0.15,max | 0.5,max |

| Cu | – | – | 0.4-0.75 | – | – | – | 0.75-1.25 | 0.15,max | – |

| Al | – | – | 0.04-0.3 | – | – | – | – | 0.06,max | – |

| V,max | – | – | – | – | – | – | – | 0.12 | – |

| Nb,max | – | – | – | – | – | – | – | 0.05 | – |

| Mo,max | – | – | – | – | – | – | – | 0.05 | 0.5,max |

| Co | – | – | – | – | – | – | – | – | 0.5,max |

| Mn | 0.40-1.06 | 0.31-0.64 | 0.5-1.05 | 0.29-1.06 | 0.9,max | 0.9,max | 0.4-1.06 | 1.15-1.5 | 0.6,max |

ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes Mechanical Properties

| Mechanical properties | |||||||||

| GRADE | 1 | 3 | 4 | 6 | 7 | 8 | 9 | 10 | 11 |

| Tensile strength, min,Mpa | 380 | 450 | 415 | 415 | 450 | 690 | 435 | 550 | 450 |

| Yield strength, min,Mpa | 205 | 240 | 240 | 240 | 240 | 515 | 315 | 450 | 240 |

| Elongation,min, (s≥8mm) | 35% | 30% | 30% | 30% | 30% | 22% | 28% | 22% | 18% |

| Elongation, min, (Standard circle) | 28% | 22% | 22% | 22% | 22% | 16% | – | 16% | – |

| Elongation(s<8mm) Percentage reduction from basic each reduction of 8mm of wall thickness | 1.75 | 1.5 | 1.5 | 1.5 | 1.5 | 1.25 | 1.5 | 1.25 | – |

Impact Requirements FOR astm a333 Grade 6 seamless pipes

| Size of Specimen, min | Minimum Average Notched Bar Impact Value of Each Set of Three Specimens | Minimum Notched Bar Impact Value of One Specimen Only of a Set | Impact Temperature | ||||

| ft-lbf | J | ft-lbf | J | Grade | Min Impact Test Temp |

||

| 10 by 10 | 13 | 18 | 10 | 14 | F | C | |

| 10 by 7.5 | 10 | 14 | 8 | 11 | 1 | -50 | -45 |

| 10 by 6.67 | 9 | 12 | 7 | 9 | 3 | -150 | -100 |

| 10 by 5 | 7 | 9 | 5 | 7 | 6 | -50 | -45 |

| 10 by 3.33 | 5 | 7 | 3 | 4 | |||

| 10 by 2.5 | 4 | 5 | 3 | 4 | |||

Bulk Stock of ASTM A333 Gr. 6 Carbon Steel Pipes, Rate of CS A333 Gr. 6 Boiler Tubes in India, Check online A333 Grade 6 Carbon Steel Capillary Tubing Pressure Ratings, Largest A333 Gr. 6 Round Pipe Stockist in India, We offer A333 Gr. 6 Carbon Steel Welded Pipes in almost all Sizes.

Weight Chart & Dimentions Of ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

|

PIPE

SIZE |

OD

IN INCHES |

A.S.A. Pipe Schedules

|

|||||||||||||||

|

5s

|

5

|

10s

|

10

|

20

|

30

|

40s

& Std. |

40

|

60

|

80s

& E.H. |

80

|

100

|

120

|

140

|

160

|

DBL

E.H. |

||

|

1/8

|

.405

|

|

.035

.1383 |

.049

.1863 |

.049

.1863 |

|

|

.068

.2447 |

068

.2447 |

|

0.95

.3145 |

0.95

.3145 |

|

|

|

|

|

|

1/4

|

.540

|

|

.049

.2570 |

.065

.3297 |

.065

.3297 |

|

|

.088

.4248 |

088

.4248 |

|

.119

.5351 |

.119

.5351 |

|

|

|

|

|

|

3/8

|

.675

|

|

.049

.3276 |

.065

.4235 |

.065

.4235 |

|

|

.091

.5676 |

.091

.5676 |

|

.126

.7338 |

.126

.7338 |

|

|

|

|

|

|

1/2

|

.840

|

.065

.5383 |

.065

.5383 |

.083

.6710 |

.083

.6710 |

|

|

.109

.8510 |

.109

.8510 |

|

.147

1.088 |

.147

1.088 |

|

|

|

.187

1.304 |

.294

1.714 |

|

3/4

|

1.050

|

.065

.6838 |

.065

.6838 |

.083

.8572 |

.083

.8572 |

|

|

.113

1.131 |

.113

1.131 |

|

.154

1.474 |

.154

1.474 |

|

|

|

.218

1.937 |

.308

2.441 |

|

1

|

1.315

|

.065

.8678 |

.065

.8678 |

.109

1.404 |

.109

1.404 |

|

|

.133

1.679 |

.133

1.679 |

|

.179

2.172 |

.179

2.172 |

|

|

|

.250

2.844 |

.358

3.659 |

|

1-1/4

|

1.660

|

.065

1.107 |

.065

1.107 |

.109

1.806 |

.109

1.806 |

|

|

.140

2.273 |

.140

2.273 |

|

.191

2.997 |

.191

2.997 |

|

|

|

.250

3.765 |

.382

5.214 |

|

1-1/2

|

1.900

|

.065

1.274 |

.065

1.274 |

.109

2.085 |

.109

2.085 |

|

|

.145

2.718 |

.145

2.718 |

|

.200

3.631 |

.200

3.631 |

|

|

|

.281

4.859 |

.400

6.408 |

|

2

|

2.375

|

.065

1.604 |

.065

1.604 |

.109

2.638 |

.109

2.638 |

|

|

.154

3.653 |

.154

3.653 |

|

.218

5.022 |

.218

5.022 |

|

|

|

.343

7.444 |

.436

9.029 |

|

2-1/2

|

2.875

|

.083

2.475 |

.083

2.475 |

.120

3.531 |

.120

3.531 |

|

|

.203

5.793 |

.203

5.793 |

|

.276

7.661 |

.276

7.661 |

|

|

|

.375

10.01 |

.552

13.70 |

|

3

|

3.500

|

.083

3.029 |

.083

3.029 |

.120

4.332 |

.120

4.332 |

|

|

.216

7.576 |

.216

7.576 |

|

.300

10.25 |

.300

10.25 |

|

|

|

.437

14.32 |

.600

18.58 |

|

3-1/2

|

4.000

|

.083

3.472 |

.083

3.472 |

.120

4.973 |

.120

4.973 |

|

|

.226

9.109 |

.226

9.109 |

|

.318

12.51 |

.318

12.51 |

|

|

|

|

.636

22.85 |

|

4

|

4.500

|

.083

3.915 |

.083

3.915 |

.120

5.613 |

.120

5.613 |

|

|

.237

10.79 |

.237

10.79 |

.281

12.66 |

.337

14.98 |

.337

14.98 |

|

.437

19.01 |

|

.531

22.51 |

.674

27.54 |

|

4-1/2

|

5.000

|

|

|

|

|

|

|

.247

12.53 |

|

|

.355

17.61 |

|

|

|

|

|

.710

32.53 |

|

5

|

5.563

|

.109

6.349 |

.109

6.349 |

.134

7.770 |

.134

7.770 |

|

|

.258

14.62 |

.258

14.62 |

|

.375

20.78 |

.375

20.78 |

|

.500

27.04 |

|

.625

32.96 |

.750

38.55 |

|

6

|

6.625

|

.109

7.585 |

.109

7.585 |

.134

9.290 |

.134

9.290 |

|

|

.280

18.97 |

.280

18.97 |

|

.432

28.57 |

.432

28.57 |

|

.562

36.39 |

|

.718

45.30 |

.864

53.16 |

|

7

|

7.625

|

|

|

|

|

|

|

.301

23.57 |

|

|

.500

38.05 |

|

|

|

|

|

.875

63.08 |

|

8

|

8.625

|

.109

9.914 |

.109

9.914 |

.148

13.40 |

.148

13.40 |

.250

22.36 |

.277

24.70 |

.322

28.55 |

.322

28.55 |

.406

35.64 |

.500

43.39 |

.500

43.39 |

.593

50.87 |

.718

60.93 |

.812

67.76 |

.906

74.69 |

.885

72.42 |

|

9

|

9.625

|

|

|

|

|

|

|

.342

33.90 |

|

|

.500

48.72 |

|

|

|

|

|

|

|

10

|

10.750

|

.134

15.19 |

.134

15.19 |

.165

18.65 |

.165

18.70 |

.250

28.04 |

.307

34.24 |

.365

40.48 |

.365

40.48 |

.500

54.74 |

.500

54.74 |

.593

64.33 |

.718

76.93 |

.843

89.20 |

1.000

104.10 |

1.125

115.70 |

|

|

11

|

11.750

|

|

|

|

|

|

|

.375

45.55 |

|

|

.500

60.07 |

|

|

|

|

|

|

|

12

|

12.750

|

.156

21.07 |

.165

22.18 |

.180

24.16 |

.180

24.20 |

.250

33.38 |

.330

43.77 |

.375

49.56 |

.406

53.53 |

.562

73.16 |

.500

65.42 |

.687

88.51 |

.843

107.20 |

1.000

125.50 |

1.125

139.70 |

1.312

160.3 |

|

|

14

|

14.000

|

.156

23.07 |

|

.188

27.73 |

.250

36.71 |

.312

45.38 |

.375

54.57 |

.375

54.57 |

.437

63.37 |

.593

84.91 |

.500

72.09 |

.750

106.10 |

.937

130.70 |

1.093

150.70 |

1.250

170.20 |

1.406

189.10 |

|

|

16

|

16.000

|

.165

27.90 |

|

.188

31.75 |

.250

42.05 |

.312

52.36 |

.375

62.58 |

.375

62.58 |

.500

82.77 |

.656

107.50 |

.500

82.77 |

.843

136.50 |

1.031

164.80 |

1.218

192.30 |

1.427

223.50 |

1.593

245.10 |

|

|

18

|

18.000

|

.165

31.43 |

|

.188

35.76 |

.250

47.39 |

.312

59.03 |

.437

82.06 |

.375

70.59 |

.562

104.20 |

.750

138.20 |

.500

93.45 |

.937

170.80 |

1.156

208.00 |

1.375

244.10 |

1.562

274.20 |

1.781

308.50 |

|

|

20

|

20.000

|

.188

39.78 |

|

.218

46.05 |

.250

52.73 |

.375

78.60 |

.500

104.10 |

.375

78.60 |

.593

122.90 |

.812

166.40 |

.500

104.10 |

1.031

208.90 |

1.280

256.10 |

1.500

296.40 |

1.750

341.10 |

1.968

379.00 |

|

|

22

|

22.000

|

.188

43.80 |

|

.218

50.71 |

.250

58.07 |

.375

86.61 |

.500

114.81 |

.375

86.61 |

|

.875

197.41 |

.500

114.81 |

1.125

250.81 |

1.375

302.88 |

1.625

353.61 |

1.875

403.00 |

2.125

451.06 |

|

|

24

|

24.000

|

.218

55.37 |

|

.250

63.41 |

.250

63.41 |

.375

94.62 |

.562

140.80 |

.375

94.62 |

.687

171.20 |

.968

238.10 |

.500

125.50 |

1.218

296.40 |

1.531

367.40 |

1.812

429.40 |

2.062

483.10 |

2.344

542.13 |

|

|

26

|

26.000

|

|

|

|

.312

85.60 |

.500

136.17 |

|

.375

102.63 |

|

|

.500

136.17 |

|

|

|

|

|

|

|

28

|

28.000

|

|

|

|

.312

92.26 |

.500

146.85 |

.625

182.73 |

.375

110.64 |

|

|

|

|

|

|

|

|

|

|

30

|

30.000

|

.250

79.43 |

|

.312

98.93 |

.312

98.93 |

.500

157.53 |

.625

196.08 |

.375

118.65 |

|

|

.500

157.53 |

|

|

|

|

|

|

|

32

|

32.000

|

|

|

|

.312

105.59 |

.500

168.21 |

.625

209.43 |

.375

126.66 |

.688

230.08 |

|

.500

168.21 |

|

|

|

|

|

|

|

34

|

34.000

|

|

|

|

.312

112.25 |

.500

178.89 |

.625

222.78 |

.375

134.67 |

.688

244.77 |

|

|

|

|

|

|

|

|

|

36

|

36.000

|

|

|

|

.312

118.92 |

|

.625

236.13 |

.375

142.68 |

.750

282.35 |

|

.500

189.57 |

|

|

|

|

|

|

| Medium Type = Wall thickness in inches Bold Type = Steel weight per foot in pounds |

|||||||||||||||||

Outside Diameter, OD (in mm) & Wall Thickness, WT (in mm) Of ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

| Nominal size [inches] | Outside diameter [inches] | Outside diameter [mm] | Wall thickness [inches] | Wall thickness [mm] | Weight [lb/ft] | Weight [kg/m] |

|---|---|---|---|---|---|---|

| 1/2 | 0.840 | 21.3 | 0.083 | 2.11 | 0.68 | 1.00 |

| 3/4 | 1.050 | 26.7 | 0.083 | 2.11 | 0.87 | 1.29 |

| 1 | 1.315 | 33.4 | 0.109 | 2.77 | 1.41 | 2.11 |

| 1 1/4 | 1.660 | 42.2 | 0.109 | 2.77 | 1.82 | 2.71 |

| 1 1/2 | 1.900 | 48.3 | 0.109 | 2.77 | 2.1 | 3.13 |

| 2 | 2.375 | 60.3 | 0.109 | 2.77 | 2.66 | 3.96 |

| 2 1/2 | 2.875 | 73.0 | 0.120 | 3.05 | 3.56 | 5.29 |

| 3 | 3.500 | 88.9 | 0.120 | 3.05 | 4.37 | 6.50 |

| 3 1/2 | 4.000 | 101.6 | 0.120 | 3.05 | 5.01 | 7.46 |

| 4 | 4.500 | 114.3 | 0.120 | 3.05 | 5.66 | 8.42 |

| 5 | 5.563 | 141.3 | 0.134 | 3.40 | 7.82 | 11.64 |

| 6 | 6.625 | 168.3 | 0.134 | 3.40 | 9.35 | 13.91 |

| 8 | 8.625 | 219.1 | 0.148 | 3.76 | 13.50 | 20.10 |

| 10 | 10.750 | 273.1 | 0.165 | 4.19 | 18.79 | 27.96 |

| 12 | 12.750 | 323.9 | 0.180 | 4.57 | 24.34 | 36.22 |

| 14 | 14.000 | 355.6 | 0.188 | 4.78 | 27.97 | 41.62 |

| 16 | 16.000 | 406.4 | 0.188 | 4.78 | 32.02 | 47.65 |

| 18 | 18.000 | 457.0 | 0.188 | 4.78 | 36.05 | 53.65 |

| 20 | 20.000 | 508.0 | 0.218 | 5.54 | 46.42 | 69.09 |

| 22 | 22.000 | 559.0 | 0.218 | 5.54 | 51.14 | 76.10 |

| 24 | 24.000 | 610.0 | 0.250 | 6.35 | 63.93 | 95.13 |

| 30 | 30.000 | 762.0 | 0.312 | 7.92 | 99.60 | 148.22 |

Largest Inventory Of ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes

- CS A333 Gr. 6 Seamless Tube

- A333 Gr. 6 Condencer Tubes

- CS A333 Gr. 6 Welded Tube

- ASTM A333 Gr. 6 Carbon Steel Capillary Tubing

- ASTM A333 Gr. 6 Carbon Steel Tubes

- Carbon Steel A333 Gr. 6 Pipes

- ASTM A333 Gr. 6 Carbon Steel Pipes

- A333 Grade 6 Carbon Steel Seamless Pipes

- ASTM A333 Gr. 6 Carbon Steel Heat Exchanger Pipe

- A333 Gr. 6 Welded Pipes

- ASTM A333 Gr. 6 Carbon Steel Seamless Tubing

- A333 Gr. 6 Carbon Steel Spiral Welded Tube

- CS A333 Gr. 6 Boiler Tubes

- ASTM A333 Gr. 6 Carbon Steel PN 10 Pipe

- ASTM A333 Gr. 6 Carbon Steel Tubing

- Carbon Steel A333 Gr. 6 Square Tube

- ASTM A333 Gr. 6 Carbon Steel Round Pipe

- Carbon Steel A333 Gr. 6 ERW Pipes

- ASTM A333 Gr. 6 Carbon Steel Welded Pipes

- ASTM A333 Gr. 6 Carbon Steel Seamless Tubing

- A333 Gr. 6 Tube

- ASTM A333 Gr. 6 Carbon Steel Round Tubes

- Carbon Steel A333 Gr. 6 Heat Ex-changer Tubes

- ASTM A333 Gr. 6 Carbon Steel Welded Pipe

- A333 Gr. 6 Industrial Pipes

- ASTM A333 Gr. 6 Carbon Steel Pipe

- Carbon Steel A333 Gr. 6 Large Pipes

- ASTM A333 Gr. 6 Carbon Steel Seamless Piping

- A333 Gr. 6 Carbon Steel Square Pipe

- CS A333 Gr. 6 Pipes

- ASTM A333 Gr. 6 Carbon Steel ERW Pipe

- Carbon Steel A333 Gr. 6 Beveled End Pipes

- A333 Grade 6 Carbon Steel Tubing

- ASTM A333 Gr. 6 Carbon Steel Thick Wall Pipe

- A333 Gr. 6 Carbon Steel Welded Tube

- CS A333 Gr. 6 EFW Pipes

- A333 Grade 6 Carbon Steel Round Pipe

- ASTM A333 Gr. 6 Carbon steel Seamless Tube

ASTM A333 Gr. 6 Carbon Steel Pipes & Tubes Application